Overview

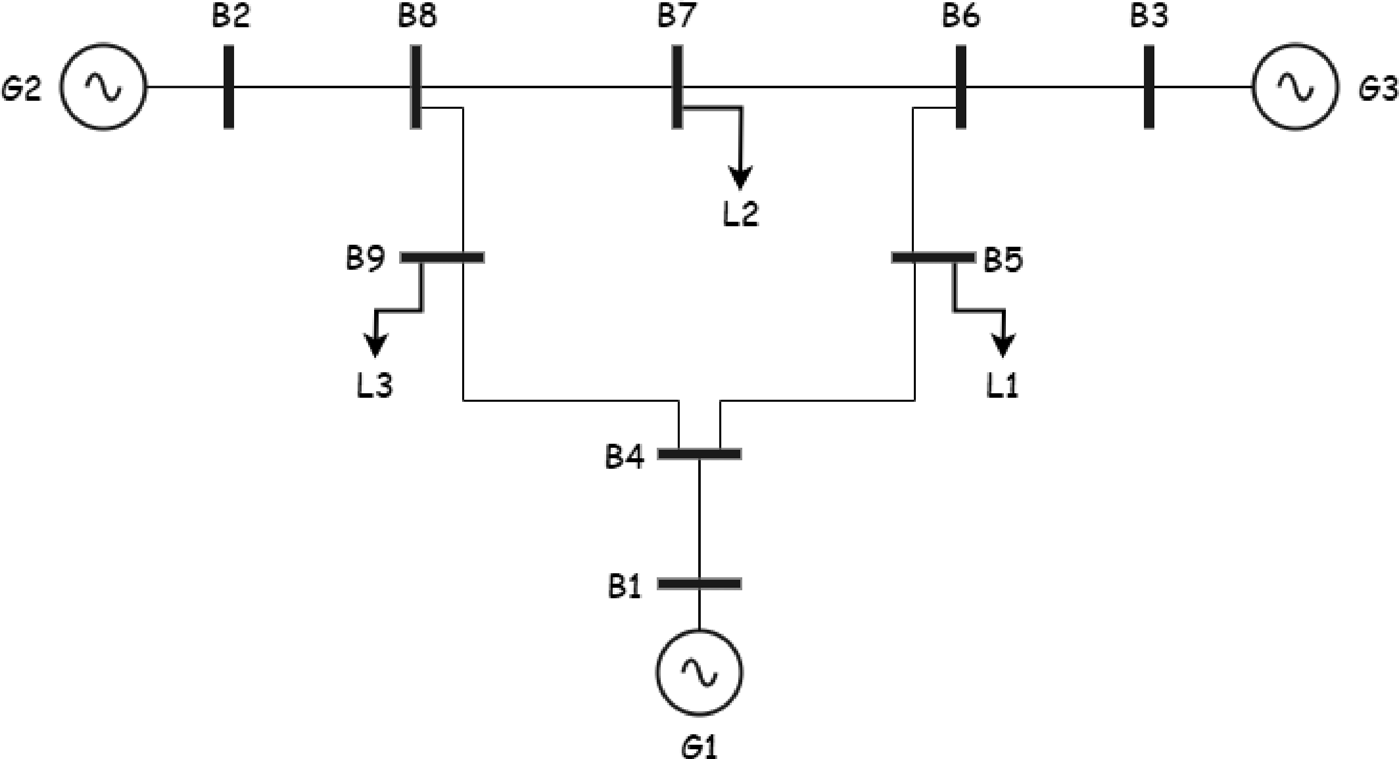

This paper proposes a multi‑objective optimisation framework designed to help nations meet ambitious decarbonisation goals by simultaneously planning renewable generation, energy storage and green‑hydrogen production. Using the IEEE nine‑bus test system as a baseline, the authors compare battery storage, pumped hydro storage (PHS), compressed air energy storage (CAES) and hybrid configurations. The optimisation accounts for techno‑economic constraints, emission caps and hydrogen demand, and is scalable to larger networks.

Key Results

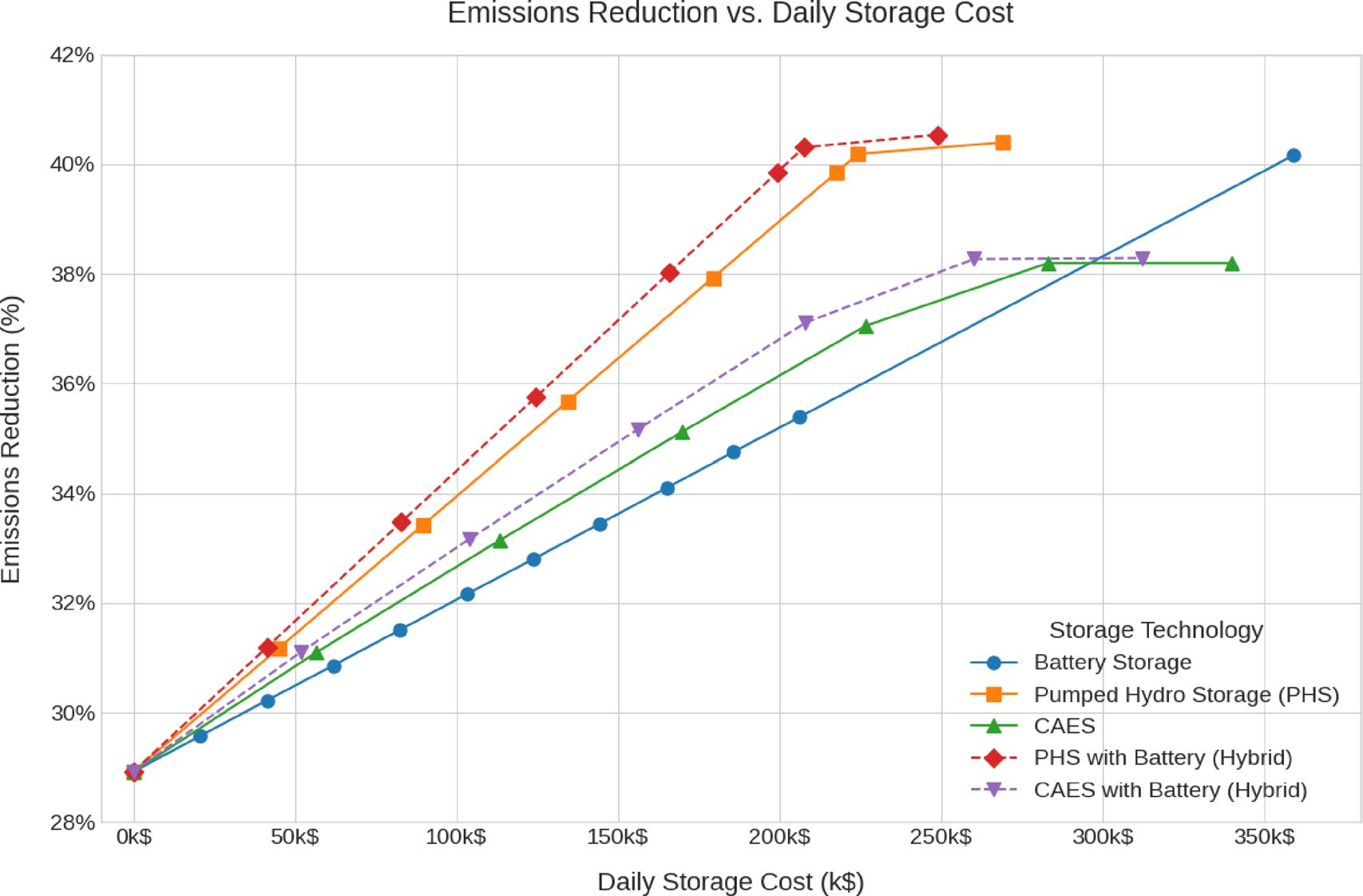

Without any storage the nine‑bus system can only accommodate roughly 28.6% renewable penetration and emits about 1538tCO2 per day [1]. Introducing storage dramatically improves performance. A pumped‑hydro–plus‑battery (PHB) hybrid configuration achieves about 40% renewable penetration, reduces emissions by approximately 40.5% and lowers total daily cost to around USD 570k — about 84% of the baseline cost [1]. Battery storage alone minimises storage losses and maximises hydrogen production (≈12t/day) but is uneconomical at ≈USD 715k per day [1]. CAES and CAES‑battery hybrids do not reach the 40% penetration threshold and require additional renewable investment.

Conclusions & Future Work

The authors conclude that the PHB hybrid strikes the best balance between renewable integration, cost and emissions. Battery storage excels at producing hydrogen but requires significant cost reductions. CAES needs further renewable investment to achieve comparable penetration. Future research directions include incorporating stochastic renewable variability, real‑time grid dynamics, demand‑side management and sector coupling (e.g., integrating with water and transport systems) [1].

Result Summary Table

| Configuration | Renewable penetration | Emissions reduction | Approx. daily cost | Notes |

|---|---|---|---|---|

| No storage | ≈28.6% | 0% | Baseline | Limited renewable integration |

| Battery | Medium | Up to ≈34% | ≈USD 715k/day | High hydrogen output but costly |

| Pumped hydro | ≈34–38% | ≈35% | ≈USD 600k/day | Cost‑effective long‑duration storage |

| PHB hybrid | ≈40% | ≈40.5% | ≈USD 570k/day | Best balance of cost and performance |

| CAES & CAES‑battery | <40% | ≈32–34% | Variable | Require additional renewables |

References

- A.M. Asim, A.S.A. Awad, M.A. Attia, A.I. Bhuiya and colleagues, “Integrated optimisation of energy storage and green hydrogen systems,” Scientific Reports (2023).